Arrington Performance has been building HEMI engines since the beginning. We specialize in applying our winning NASCAR racing technology to power up your street car. Arrington is continuously introducing innovative new applications for late model American muscle cars, classics and hot rods. The company operates from a 105,000 sq. foot facility that houses the finest race engine development, manufacturing and testing program in the business.

CNC Engine Block Decking & Cylinder Boring

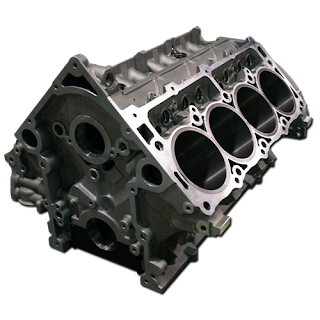

Arrington and precision are synonymous. Cylindricity, concentricity and angularity are essential to high horsepower engine manufacturing. If your cylinders are out of round or the centerline alignment is off, when force is applied to the piston through combustion or boost the results are not optimal. This CNC procedure ensures alignment of cylinders relative to the mainline, and aligns cylinder bore centers with companion cylinders.

Production blocks are production blocks, built to a range of standards that are acceptable in daily driver use. Arrington applies NASCAR level precision and technology to produce an optimized engine block suitable for use in performance applications. The misalignment of the mainline relative to the bore and the perpendicularity of the bore centerline relative to the deck are corrected to ensure all surfaces are parallel and perpendicular to the mainline.

These processes reduce friction, reduce premature wear and translate directly to production of increased reliable horse power and torque. For over thirty years Arrington has been refining the engine manufacturing process for champions. We manufacture your Arrington engine with the same technology, care and staff as our NASCAR championship engines.

Cylinder Finishing or Final Hone

Different engines require different cylinder finishes. Forced Induction engines require an aggressive finish to insure cylinder sealing. Normally Aspirated engines are honed to a medium finish. NASCAR Sprint Cup engines are honed to a diamond mirror finish. Arrington selects the proper finish based on your intended use. Every cylinder has to be finished properly to perform at its peak, without creating frictional loss. Different roughness and RA scales are used for precise cylinder finishes to ensure quality sealing and combustion.

Crank Balancing

Balancing only takes one machine. Adding or removing material is what produces a balanced final product. That takes another 2 machines. We use CNC Lathes and 3 axis CNC drill presses to remove or add material to the crank then return to the balancer for evaluation. After that we polish the crank to remove any surfaces that can trap oil or fine particles. So in total our balanced HEMI crankshaft takes 4 machines to produce. Sound complicated? We do all this to the gram and the .0001” so that our crankshafts produce no vibrations and are perfectly balanced. Every counterweight, rod journal, and main journal is machined to the exact size and weight proper for your application. Ask other engine builders how many machines they use...

Valve Seats

When we are asked how many angles our valve job is we say none. Our Newen Epoc CNC valve job is a single point operation. The angles and steps are so small that they are reduced to a near true radius. From there the heads are taken to a 5 axis CNC mill where ports specifically designed to produce maximum air velocity from intake and exhaust ports are machined. Finally these heads are taken to assembly where strengthened springs, keepers, and retainers are installed in the casting. Why accept the industry standard stock hardware, 3 point valve job, and a fluff and buff port when looking for maximum performance?

The Machine Shop

Available for a custom job for hire or to assist our techs with a modification needed for proper installation of your hemi engine, our complete machine shop is ready to work. You name it; we can do it down to the smallest of details or the roughest of cuts. 4 -5 full axis CNC machines and a host of other smaller machines, lathes, and measurement tools are precise down to measurements that the human eye will never see and can be utilized for one off tooling or volume production.

And we’re back to inspection and assembly.

After a final check on tolerances your HEMI is assembled by an expert engine builder. Torque is applied every bolt. Piston to valve clearance is double checked. Cam timing and bearing clearances are verified. Finally front dress, accessories, and belt tension and pulley alignment is adjusted.

From an assembly bay to your high horsepower street car

You can ensure our NASCAR proven power, technology and research and development will all be included in YOUR aftermarket package. All processes take place in our climate controlled and ultra clean shop to ensure accuracy and detail.

Dyno and Tuning

At the end of the install, your build is dyno tuned on a SuperFlow certified chassis dyno. Not your standard roll away dyno, this eddy current precision dyno has separate climate controls and fire suppressant systems. When we tune your HEMI and your ride leaves our shop, you won’t just happy - you’ll be impressed.

Increase the power of your HEMI engine with Magnuson’s MP2300 TVS Supercharger Kit. Designed for the Dodge Challenger, this bolt on supercharger will deliver maximum performance while retaining Dodge-like drivability and reliability. At 6 pounds of boost this supercharger produces approximately 120 horsepower and 120 foot-pounds of torque to the wheels. However, peak horsepower and torque numbers don’t tell the whole story. "Under the curve" power is significantly enhanced delivering near instantaneous boost and torque response that really pins you back in your seat.

Inside of the HEMI supercharger manifold, a large liquid-to-air intercooler keeps your Intake Air Temperatures in check and provides consistent and repeatable performance. Combine that with the front-mounted heat exchanger, electric water pump, and intercooler coolant reservoir and you have a supercharger system that has IATs that are typically only 20-40 degrees (Fahrenheit) over the ambient temperature.

Maximizing your efficiency during cruising is the job of the supercharger’s integrated bypass valve. This vacuum operated system allows air to bypass the supercharger and the rotors to “free-spin" under light engine loads. During this situation the parasitic loss of the supercharger system is essentially negated taking less than one-third of a horsepower to turn the rotors. This bypass valve also allows your supercharged Challenger to maintain stock-like drivability and fuel economy - giving you a package that delivers power without compromise.

Down to the smallest part, our MagnaCharger line of bolt-on supercharger systems are engineered as a complete package. The supercharger, supercharger intake manifold, inlet, pulley, fuel injectors, fuel rails, front & rear fuel crossovers, and intercooler come pre-assembled to make installation simple and easy while the accessory box is organized into individual sub-assemblies to help ensure that you don’t lose track of parts during the installation process. All of the hardware needed for a full and complete install is also included so you won’t be running to the local parts store in the middle of your installation. In addition, our full color, step-by-step Installation Manuals will walk you through the install process with exacting attention to detail.

Magnuson’s MP2300 TVS supercharger utilizes EATON’s latest 6th Generation supercharger rotor technology featuring a pair of four-lobe, high-helix rotors with 160-degrees of overall twist that are housed in Magnuson’s patented high-flow housing. This highly efficient package requires less power to drive, delivers cooler discharge temperatures, and is much quieter than many of its competitors. These superchargers are all manufactured in our TS16949 certified facility – the highest ISO OEM quality certification standard in the market.

Backed by a 3-year/36,000 mile warranty this supercharger is built to last. Designed to be nearly maintenance free you won’t have to worry about anything once it is installed. And for those that don’t want to have to stress about voiding their factory powertrain warranty we offer a solution for that as well. Our optional powertrain warranties will give you the peace-of-mind to be able to enjoy your supercharger without having to worry about those “what if" scenarios. Available with 3-years/36,000 miles, 5-year/60,000 miles, or 5-years/100,000 miles of protection and covering up to $5,000 on the motor, $1,500 on the transmission, and $1,500 on the rear-end with NO deductible you can choose the level of coverage that is right for you. But these protection plans won’t break the bank either – ranging from just $275 for the 3-year/36,000 mile plan to $775 for the 5-year/100,000 mile plan.

For more information visit www.magnacharger.com.

JBA long tube headers are the number one choice for maximum performance gains and high RPM efficiency. These long tube designs are dyno and race proven to deliver the greatest possible increase in horsepower and torque throughout the RPM range. All JBA long tube headers feature large mandrel-bent stainless steel primary tubes, oversized exhaust ports, extra thick 3/8” one piece flanges, and patented JBA Firecone®* merged collectors for smooth flow. Each system is designed to give the maximum amount of ground clearance possible so lowered cars do not drag the collectors on speed bumps. Each system includes high quality hardware and thorough instructions for a professional no-leak installation.

JBA mid-pipes are the perfect compliment to your JBA Headers or JBA Exhaust system. These systems open up the flow on exhaust systems for a dramatic increase in performance and improved sound. They are available for many popular applications as a stand alone upgrade or an addition to existing JBA product. Each system is application specific and optimized for your vehicle to get a perfect fit every time. They feature smooth flowing mandrel-bent tubing, heavy duty flanges, factory style hangers and provisions for factory emissions equipment for a simple installation.

When it comes to performance exhaust systems, most people are looking for three things: Power, sound, and quality. JBA Exhaust Systems deliver the best of all three, giving it both great looks and performance. One of the first performance upgrades typically made to a vehicle is the addition of a performance exhaust system. While there is a high demand for performance sound. the capacity for power in a JBA exhaust system gives JBA the extra edge. Each system is tuned to provide the best possible exhaust tone without being overwhelming from within the vehicle. By replacing the restrictive factory exhaust system with free flowing mandrel-bent stainless tubing and quality performance mufflers, JBA has developed the power, sound, and efficiency desired in a vehicle. Each kit is finished with a polished chrome plated stainless steel tip that resist discoloring, along with high quality hardware and thorough instructions for a simple bolt-on installation.

For more information visit www.jbaheaders.com

More information coming soon...